Camloc® 2600 & 2700 series rivet type receptacles

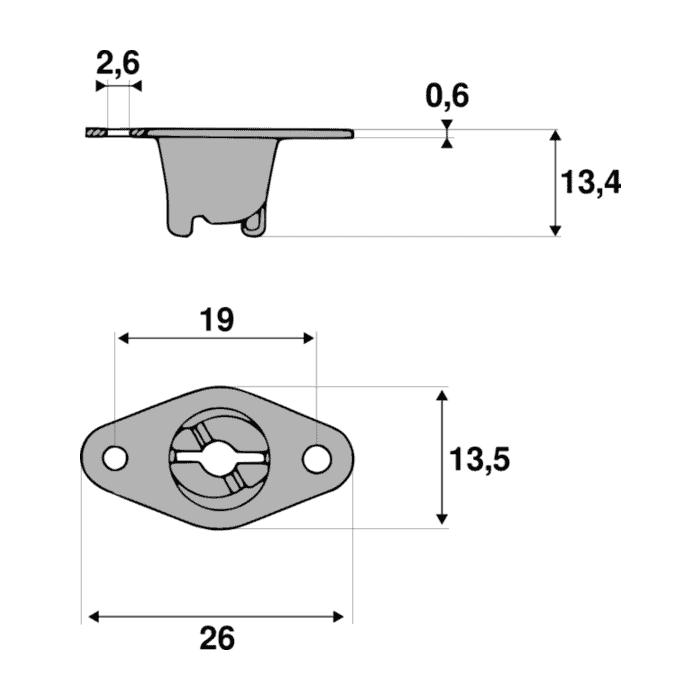

V26R6-1AGV lightweight receptacle

This lightweight receptacle is made of steel and is zinc plated (CrVI-free, clear passivation). The maximum application temperature is 120 °C.

The rivet holes are 2,6mm so installation can be done with 2.4mm (or 3/32″) diameter rivets.

The rivet holes are 2,6mm so installation can be done with 2.4mm (or 3/32″) diameter rivets.

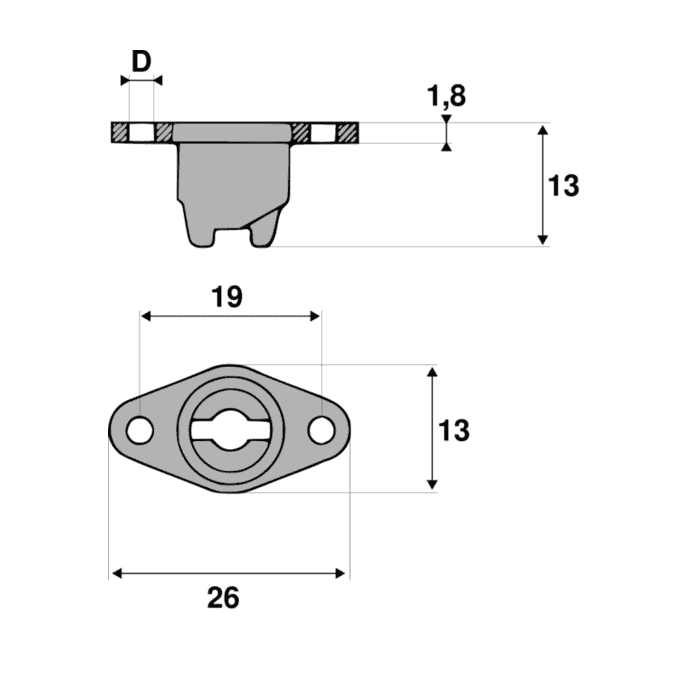

V212-12-1FGV and V212-12-2FGV cast receptacles

These cast receptacles are made of hard bronze and are zinc plated (CrVI-free, clear passivation). The maximum application temperature is 120 °C.

For V212-12-1FGV, the rivet holes are 2,5mm so installation can be done with 2.4mm (or 3/32″) diameter rivets.

For V212-12-1FGV, the rivet holes are 2,5mm so installation can be done with 2.4mm (or 3/32″) diameter rivets.

For V212-12-2FGV, the rivet holes are 3,3mm so installation can be done with 3,2mm (or 1/8″) diameter rivets.

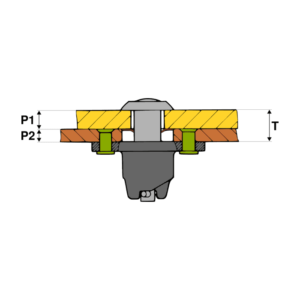

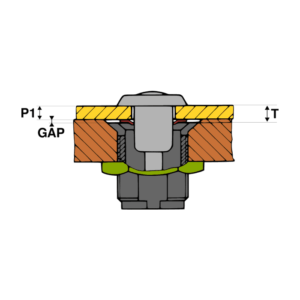

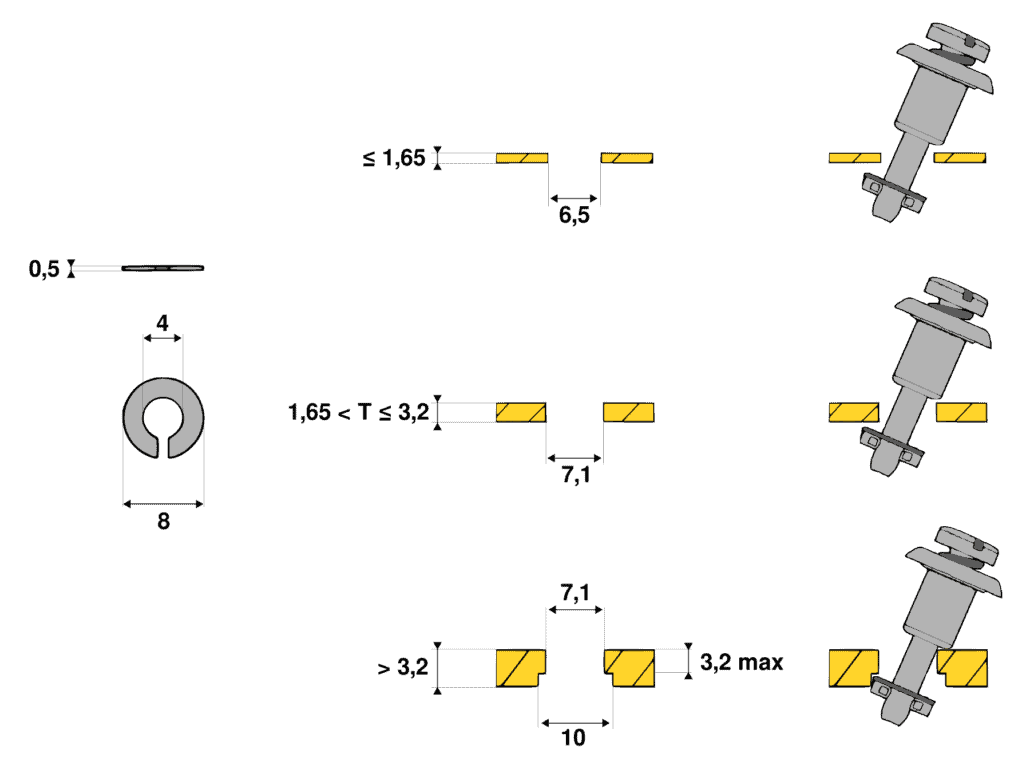

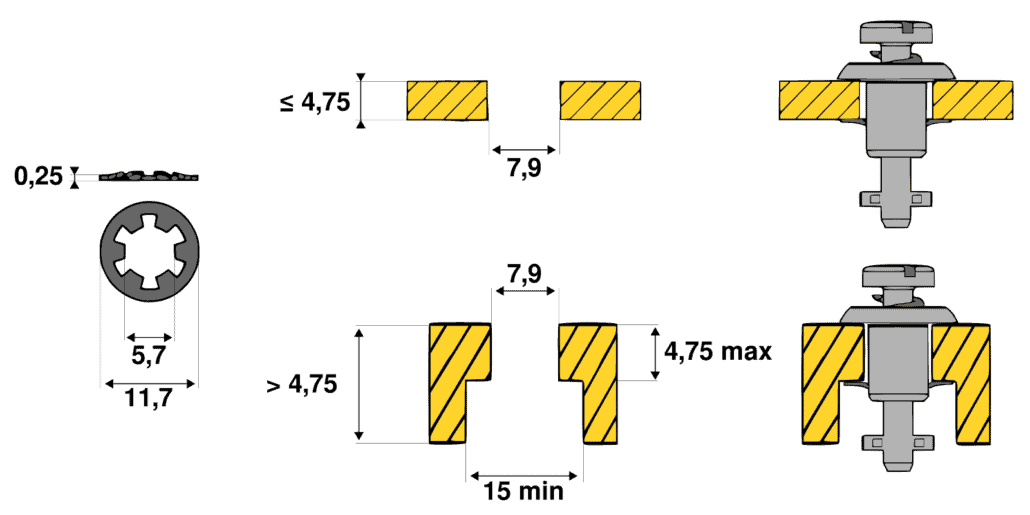

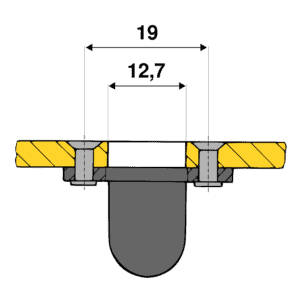

Installation instructions for the rivet type receptacles

To prepare the bottom panel B for the receptacle, please follow these steps:

To prepare the bottom panel B for the receptacle, please follow these steps:

- Drill a pilot hole in the center (where the stud will finally go through).

- Drill the rivet holes with a center to center distance of 19mm.

Depending on the choosen receptacle, the diameter of these rivet holes will either be 2,5mm or 3,3mm. - Countersink the rivet holes to fit the countersink head of the choosen rivets.

- Enlarge the pilot hole to the final size with a drill of 12,7mm diameter.

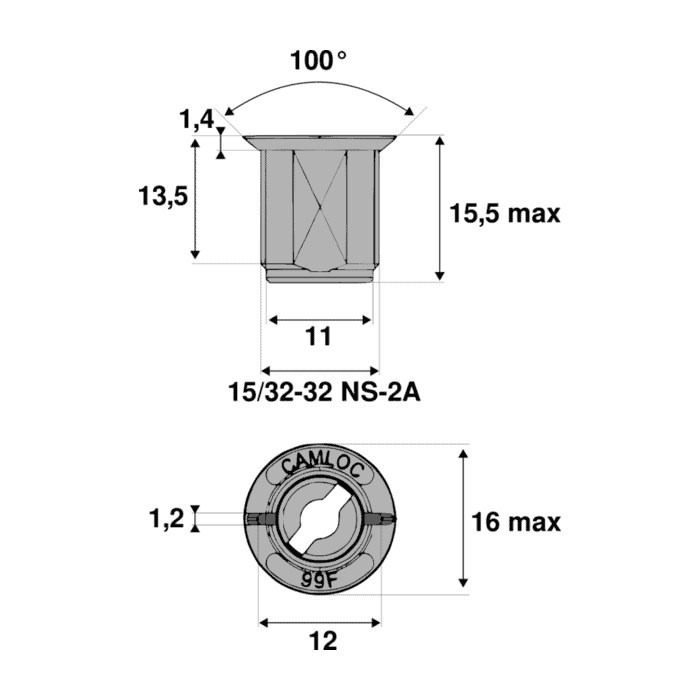

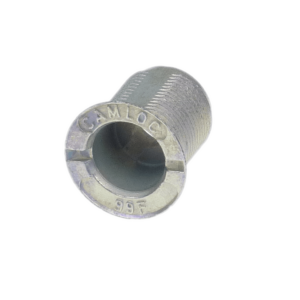

Camloc® 2600 & 2700 series threaded receptacle

99R10-01A1 threaded receptacle

This threaded receptacle is made of zinc die cast and is zinc plated (CrVI-free, clear chromate). The maximum application temperature is 100 °C.

The threaded receptacle is used for single hole mounting applications.

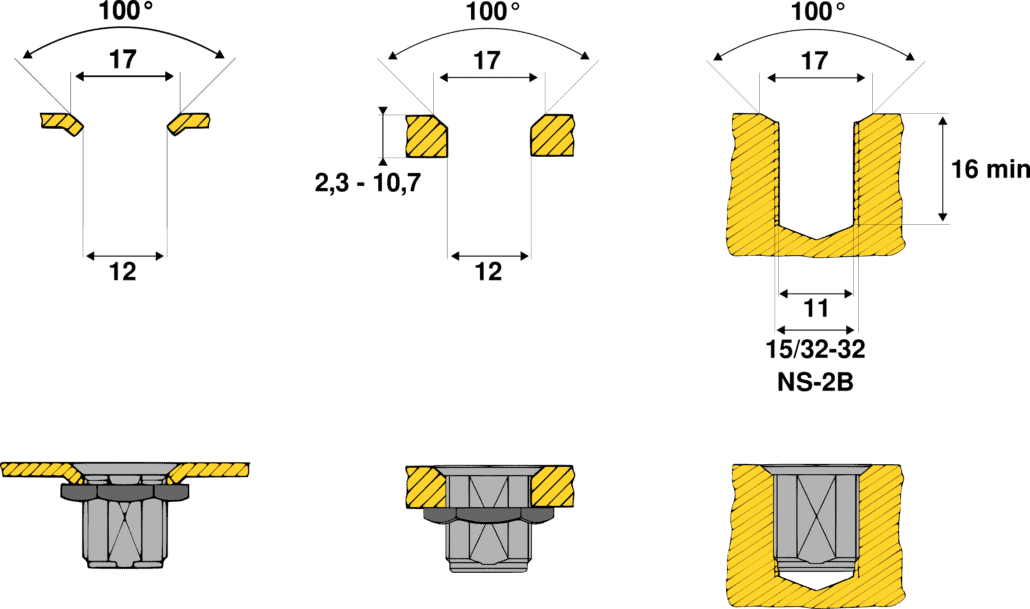

The top of the receptacle is 100° countersunk.

There are 2 options for the use of this threaded receptacle:

- installation together with the corresponding nut 99N10-01A1

- installation in a threaded hole with 15/32-32UNS-2B female thread

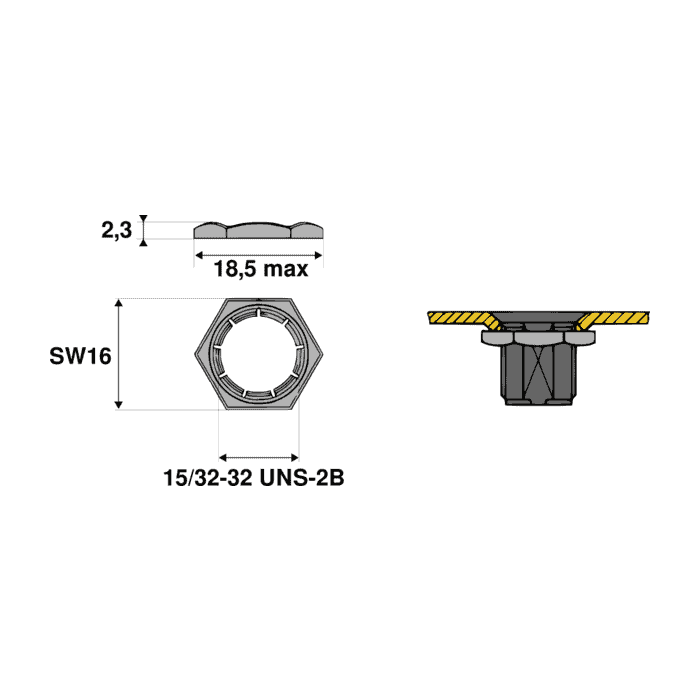

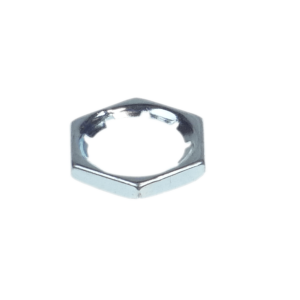

99N10-01A1 nut for threaded receptacle

This receptacle nut is made of steel and is zinc plated (CrVI-free, clear chromate). The maximum application temperature is 100 °C.

This lightweight (stamped and formed) nut has 15/32-32UNS-2B thread to fit with the 99R10-01A1 threaded receptacle.

The advised fastening torque to apply when installing this nut on the receptacle is 3 Nm.

Installation instructions for the threaded receptacle

Installation with nut for panel thickness up to 2,3mm:

Installation with nut for panel thickness up to 2,3mm:

- drill a pilot hole in the center

- enlarge the pilot hole to the final diameter of 12mm

- dimple the hole to 100° with the largest diameter at 17mm

Installation with nut for panel thickness of 2,3mm to 10,7mm:

- drill a pilot hole in the center

- enlarge the pilot hole to the final diameter of 12mm

- countersink the hole at 100° with the largest diameter at 17mm

Installation without nut:

- drill a pilot hole in the center

- enlarge the pilot hole to a diameter of 11mm

- countersink the hole at 100° with the largest diameter at 17mm

- use a 15/32-32NS-2B tap to tap the thread for the receptacle

(for a blind installation, make sure the depth of the tapped thread is at least 16mm)

Camloc® is a registered brand of Howmet Fastening Systems